Nurturing our forests from seed to stem

Our forestry operations are supported by a team of contractors who work alongside us, nurturing our forests from seed to stem. The scale of our operations, combined with our sophisticated approach to rotational harvest and constant low-waste processing, allows us to increase our yields in the most sustainable way.

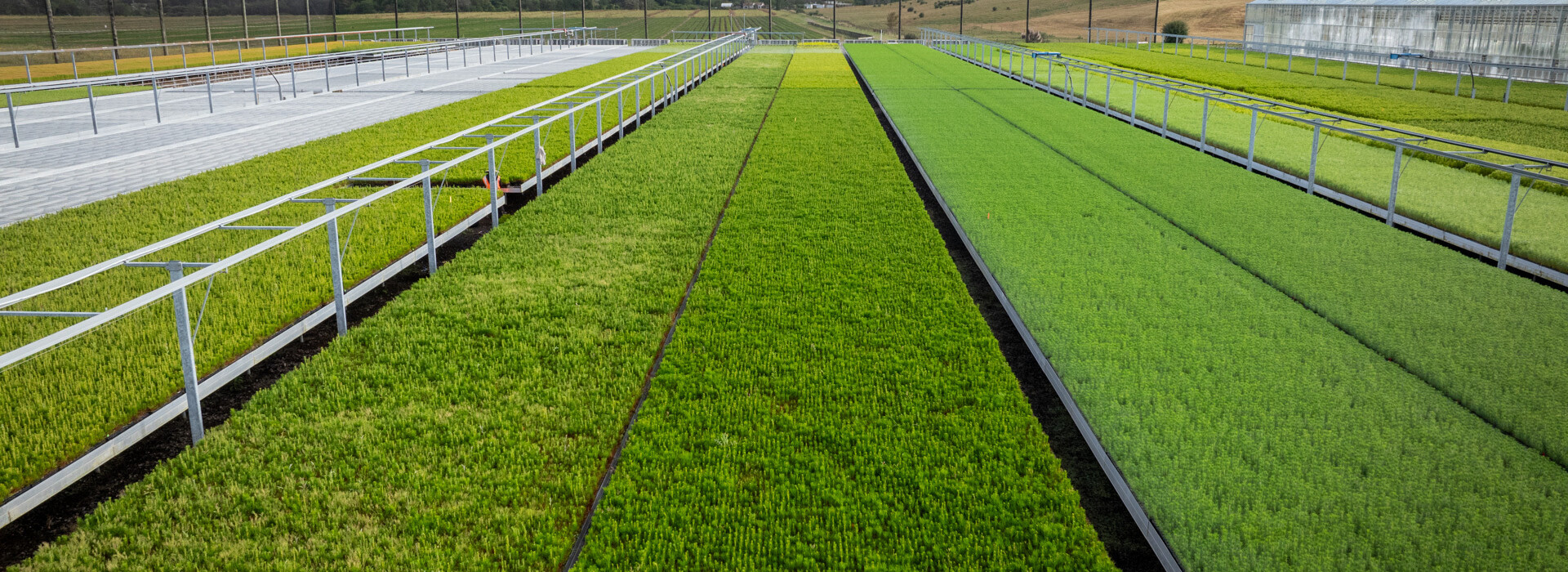

Genetics and nursery facilities

Kaingaroa Tipu operates a tree breeding and nursery facility at Te Ngae in Rotorua, and a tree nursery at Rerewhakaaitu. Our nursery team produces over seven million seedlings and cuttings each year, primarily for deployment in Kaingaroa Tipu managed forests. These facilities support the foundation of a consistent, healthy, fast growing crop of trees. Our nursery team select, nurture, and grow the best genetic breeds to ensure optimal growth and disease resistance. The high-quality seedlings they produce are the basis for robust and sustainable tree growth. Kaingaroa Tipu does not develop, propagate or plant genetically modified organisms.

Planting

We re-establish about 7,000 ha of radiata pine every year, complemented by an active minor species programme that includes cypress, eucalyptus, and other species. Prior to planting, each site undergoes meticulous planning and preparation to ensure optimal conditions for establishment. This comprehensive approach includes site preparation activities such as cultivation, raking, rolling, slashing, skid rehabilitation, and effective weed control, all of which contribute to the successful growth and sustainability of our forestry operations.

During the planting season, up to 100 people collectively plant over 10,000 trees a day. In addition to our dedicated planting contractor workforce, we also employ specialised mechanised planting machines driving innovation in the planting process. This combination of skilled labour and advanced technology allows us to optimise our efforts and contribute effectively to our forestry initiatives.

Silviculture

Our silviculture regime varies depending on each site’s terrain, soil, elevation and weed control needs. We also consider environmental, community and safety risk factors. Our key silviculture operations are pruning, waste thinning and production thinning. These techniques maximise our timber yield and growth.

Harvesting Operations

Our philosophy is to have a sustainable yield and to achieve this, on average the annual harvest equals the annual growth. As we achieve safe and sustainable productivity gains, our sustained yield increases. Across the entire estate, our radiata pine has a relatively even age distribution, keeping our harvest levels stable over time:

- 34% of the estate is between 1-10 years old

- 36% of the estate is between 11 – 20 years old

- 30% of the estate is over 20 years old

We use three core criteria to determine how we harvest each area:

- Health and Safety: Choosing the method most suitable for the topography and nature of the land, aiming for mechanised felling whenever practical.

- Environmental: Selecting the method that minimises environmental impact.

- Economic: Opting for the most cost-effective method for the area, while considering safety and environmental factors.

Our harvesting operations fall into the following categories:

- Production thinning: The process of selectively harvesting non-crop trees, specifically those that are suppressed, defective, or diseased. This practice is essential for improving overall forest health and productivity, as it helps to reduce competition among remaining trees, promote better growth, and enhance the quality of the crop trees.

- Clear felling: The predominant harvesting system used in our forests is clear felling, where all the trees in a harvest area are cut down in one operation.

- Full stem harvesting: Full stem harvesting is carried out by ground-based extraction. The whole tree stems are loaded onto a specialised stem truck and transported to the Kaingaroa Processing Plant (KPP) on our private roading network. The KPP, located in the heart of Kaingaroa Forest, converts whole-tree stems into logs using sophisticated scanning and optimising technology.

Mechanised Harvesting

Up to 95% of our harvesting operations are mechanised, to ensure the highest levels of safety. Our comprehensive planning process decides where, how and when we carry out harvest operations. We create long-term harvest profiles that determine our annual harvest plan. This process considers tree age, safety, terrain, watercourses, protected areas, customer requirements, neighbours and other important factors and risks.

From forest to customer

The scale of our operations allows us to operate a highly efficient supply chain, a centrally located processing plant and an extensive off-highway road network designed to accommodate whole stem transportation. With our Murupara log yard, rail transport and advanced facilities at the Port of Tauranga, combined with our controlled shipping system that enhances overall efficiency, we ensure smooth operations from forest to our customers.

Products leaving the Kaingaroa Forest Estate include high value pruned logs which produce clearwood for appearance purposes, structural logs used in construction, industrial and utility logs used for packaging and remanufacturing, pulp logs used for pulp and paper products and residues used for landscaping and ground cover.